E-Coating Jewelry Explained: The Process & Benefits

- Written by Carat Island

- Last Updated on

Table of Contents

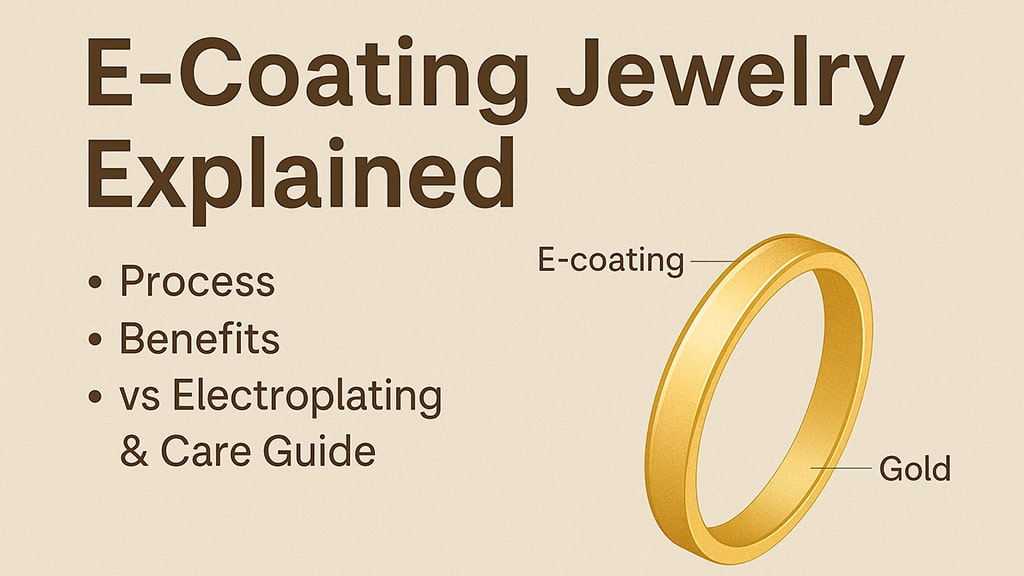

What Is E-Coating Jewelry?

E-coating, short for electro-coating or electrophoretic coating, is a protective layer applied to jewelry using electric current. It creates a thin, transparent or colored resin-based coating over metals to improve durability, resist tarnish, and enhance color longevity—especially on plated jewelry.

How the E-Coating Process Works

E-coating involves several precise steps to ensure a durable, even finish on each jewelry piece:

Pre-cleaning:

Jewelry is thoroughly cleaned to remove any dirt, oil, or polish residue. This ensures proper adhesion of the coating.Suspension:

The cleaned piece is mounted on a conductive metal rack and submerged into a liquid resin bath. This bath contains either ceramic particles or clear lacquer, depending on the desired finish.Electrodeposition:

An electric current is applied, which causes the resin particles to bond evenly and uniformly onto the jewelry’s surface.Rinsing:

Excess coating is gently washed off to prevent buildup or streaks.Curing:

The coated piece is then baked in an oven at 160°C (320°F) for about 30 minutes. This process hardens the resin into a smooth, protective shell.

This results in a uniform, ultra-thin protective layer that enhances appearance, increases durability, and provides resistance to corrosion and tarnishing.

E-coating was originally developed for use in automotive and industrial finishing before being adapted to delicate applications like jewelry. For a deeper look at the origin and evolution of this technology, here is the brief history of e-coating technology.

Types of E-Coating Finishes

E-coating offers a wide range of aesthetic options:

Transparent: Clear coating to preserve natural or plated metal color.

Colored: Shades like pink, blue, green, black, and more.

Finish styles: Glossy or matte depending on the desired look.

It can be used over gold plating, silver, brass, and other metals.

Benefits of E-Coating Jewelry

E-coating offers significant advantages for both wearers and jewelry makers:

Anti-tarnish protection for silver and plated pieces

Scratch resistance due to hardened resin shell

Color preservation: extends the vibrancy of plating or enamel

Full coverage on intricate designs and hard-to-reach spots

Durability: extends the lifespan of plated jewelry by months or even years

Limitations of E-Coating

Despite its many benefits, e-coating isn’t perfect:

Not suitable for porous or heat-sensitive materials like enamel, plastic, or fragile gemstones.

Some metals, like stainless steel, may require different surface treatments (e.g., PVD).

Coating can eventually wear off with heavy use and require re-application.

E-Coating vs Electroplating vs PVD vs Enameling

|

Feature |

E-Coating |

Electroplating |

PVD Coating |

Enameling |

|---|---|---|---|---|

|

Process |

Resin with electricity |

Thin metal layer via ions |

Vacuum vapor deposition |

Colored glass fired on |

|

Protection Level |

Medium |

Low to Medium |

High |

Medium |

|

Aesthetic Control |

High |

High |

Moderate |

Very High |

|

Heat Resistance |

Moderate (oven-cured) |

Moderate |

High |

Very High |

|

Ideal Use |

Costume & plated jewelry |

Thin gold/silver plating |

High-end stainless |

Decorative, niche |

How Long Does E-Coating Last?

The longevity of e-coated jewelry depends on wear and care:

Light, occasional use: 1–2 years

Frequent use: 3–6 months added protection

Poor care (sweat, chemicals, abrasion): coating may degrade quickly

Adding e-coating to gold-plated jewelry can significantly slow down fading and tarnishing.

Buying Jewelry with E-Coating: What to Ask

Before you buy, ask these questions:

Is this piece e-coated?

What metal is underneath?

How thick is the plating (in microns)?

Is there a palladium or anti-oxidation layer beneath the gold plating?

Has it been cured at the correct temperature?

These details help you assess how long the finish will truly last.

Jewelry Care Tips for E-Coated Jewelry

To keep your e-coated jewelry looking new:

Avoid chemicals: No perfume, alcohol, or pool water

Clean gently: Use mild soap and water with a soft cloth

Store dry: Keep in sealed pouch or box away from air & moisture

Remove before bed or heavy activities

When the coating wears off, it can often be reapplied by the manufacturer.

FAQs About E-Coating Jewelry

A: Not if it’s clear. Colored versions can alter the look intentionally.

A: Yes, it helps protect and extend the life of plated pieces.

A: Yes, as long as the base metal is hypoallergenic. The coating itself is non-reactive.

A: In most cases, yes. Contact your jeweler or manufacturer for recoating services.

Conclusion

E-coating is a valuable finishing process that boosts the durability and beauty of plated jewelry. Whether you’re a consumer or jewelry brand, understanding how it works can help you make smarter, longer-lasting purchases.

Looking for custom gold-plated jewelry with e-coating? [Contact us] to learn how we manufacture long-lasting, tarnish-resistant pieces.